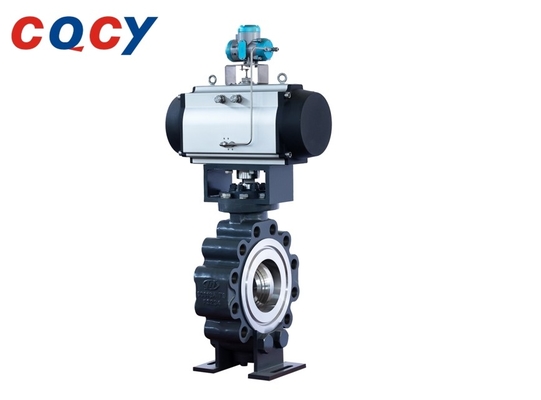

VBJG All Metal Hard Sealed Butterfly Valve -100℃~+550℃ Reliable Seal Pneumatic Butterfly Valve

| Place of Origin | Shanghai, China |

|---|---|

| Brand Name | CQCY |

| Certification | CCS/ 3A/ TUV-SII2/3 / IEC Ex/ATEX/CE/NEPSI |

| Model Number | VBJG All Metal Hard Sealed Butterfly Valve |

| Minimum Order Quantity | 1set |

| Price | USD+50 dollars to 1000 dollars+1set |

| Packaging Details | Carton packing |

| Delivery Time | 10-30 work days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 5000+1set+per day |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| 1.End-use Temperatur | -100℃~+550℃ | 2.Flange Standard | JB/T79.1-94;JB/T79.2-94;ASME B16.5-2013;HG20592-2009、HG20615-2009 |

|---|---|---|---|

| 3. Inside Nominal Diameter | DN80~DN2000(3"~80") | 4.Connection Type | Cclip Type, Flange Type, Butt Welding Type |

| 5.Sealed Surface Type | RF、MFM、RJ、BW | 6.Nominal Pressure | PN10/16/25/40/63/100/160:Class150/300/600/900/1500 |

| Highlight | VBJG Sealed Butterfly Valve,Sealed Butterfly Valve -100C,550C pneumatic butterfly valve |

||

VBJG All Metal Hard Sealed Butterfly Valve (end-use temperature -100℃~+550℃/Reliable seal and long service life)

All metal hard seal butterfly valve is a kind of three eccentric sealing butterfly valve, the sealing surface with conical type, in the horizontal center, the stem relative to the flow center in the axial and radial two distance eccentric, realize the sealing deputy in opening without friction movement, sealing ring material for the whole metal and pile welding hard alloy, ensure the whole metal butterfly valve sealing reliable, long service life and other advantages.

![]()

1. VBJG all-metal hard sealed butterfly valve adopts three eccentric structure. There is no dead zone in the valve opening and closing process, and the opening torque is small.

2, the use of high strength stainless steel material and integral valve stem structure, under the allowable pressure difference.

3, the use of independent valve seat structure, facilitate the repair and replacement of all-metal hard seal butterfly valve interior,

4. The sealing ring adopts integral metal overwelded hard alloy to improve the corrosion resistance and friction wear resistance of the whole metal butterfly valve.

5. Use the shaft seal structure to prevent the particle impurities from entering the gap between the valve body and the valve stem, to avoid the valve jamming phenomenon,

![]()

![]()